Cutting-edge ideas at 2018 TBI Smart Automation Competition

The coming of I4.0 era has been urging the rapid development of smart manufacturing and smart mechanism, and thus made Taipei Tech and TBI Motion continue co-hosting the 4th annual competition on smart automation for the university students. With NT$400,000 in the prize pool and free components provided for the teams attending, the competition has motivated dozens of groups from different universities to make an attempt on their best.

The smart automation competition received nine corporate sponsorships, including Shihlin Electric & Engineering Corporation, SESAME Motor Corp., Taiwan Chelic Co., Ltd., URA Engineering Co., Ltd., Mindman Industrial Co., Ltd., TOYO FA&ROBOT, HSK Co., Ltd., TPI Co., Ltd., and Kinik Company.

“Smart automation and engineering has been the highlighted industry of which our country has been striving for development, and so does Taipei Tech,” Taipei Tech Vice President Jen Yi Jun pointed out. “Thus, this competition carried out by the corporates and the university attendees is expected to bring in some great new ideas for the industry, and also to inspire the youth.”

“The production of automation components of different MSMEs has formed the interconnected business, which serves as the cornerstone of the smart automation industry in Taiwan, ” said Secretary-General Su Cherng Yu. “Hopefully this competition spurs the students’ learning motives, and equip them with innovative and hands-on capabilities that is beneficial to the future smart automation industry.”

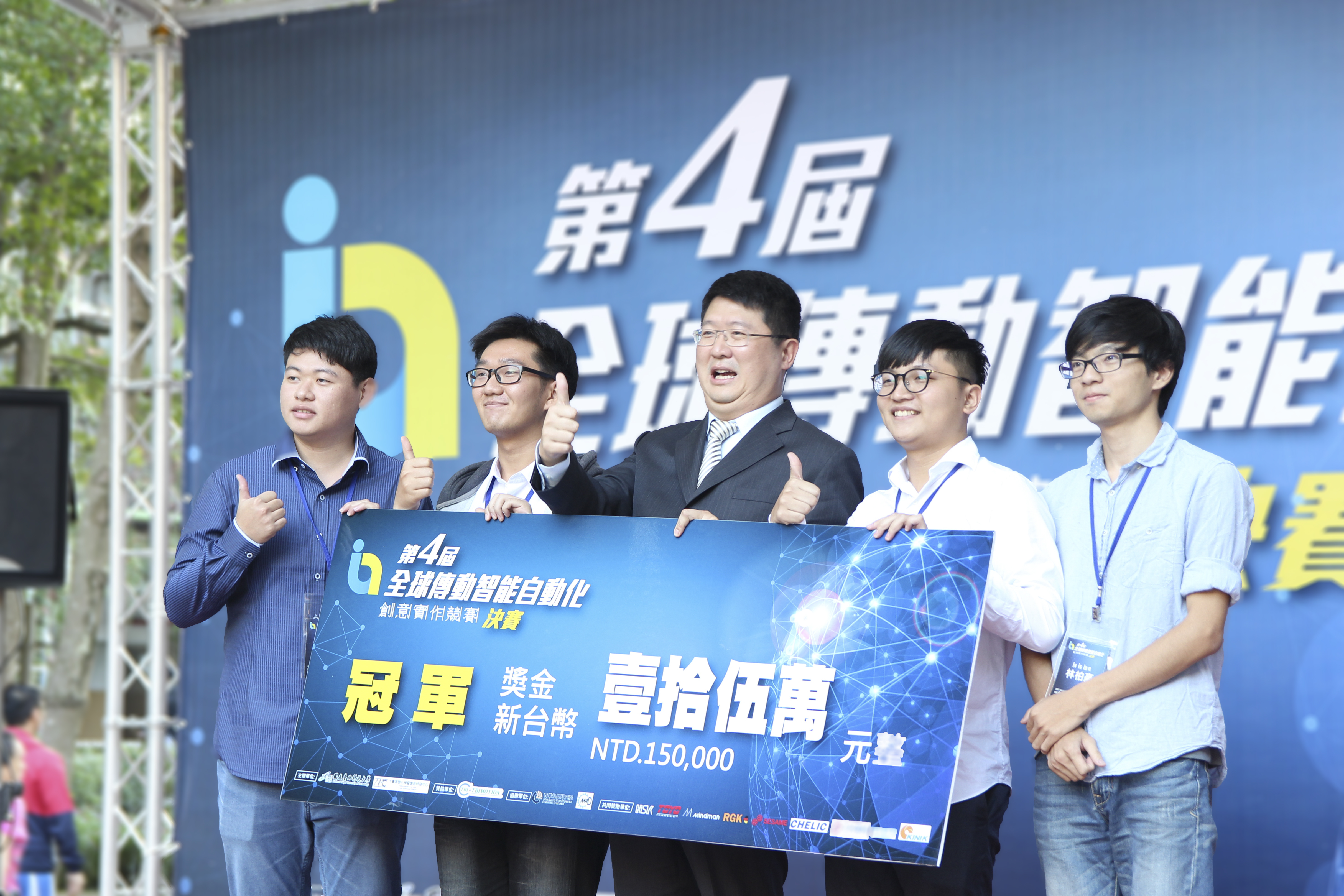

Southern Taiwan University of Science and Technology’s “ivision” team won the first place at the final stage on Dec 4, bring home NT$ 150,000 prize money as a fruitful reward for their hard work. Led by their advisor Lin Horng Horn and Su Chia Hsiang, “ivision” team members Huang Fu Chiou, Hsieh Wei Yu, and Lin Yen Ru designed the “Interactive Smart Razor Process Machine”, to replace the complicated transferring procedures between the exterior and the interior pattern through the direct order from the manipulator to the machine. The much more efficient processing is especially complimented by both the judges and the audience, and therefore made “ivision” further won the most popular prize.

The second and third place were taken by the cooperative teams from Fujen Catholic University and Lunghua University led by Professor Chiang Hsin Han and Lee Lian Wang. The production of the second place winner “ASVT” is the stable solenoid valve that controls the direction of the fluid medium with the electromagnet to implement exact actions, featured with its simpler structure, rapid reaction speed, smaller volume, lower cost, lower energy consumption, and better anti-interference. The third place winner “TAIDR” has their automatic UV-disinfection robot that completely sterilizes the seats in the long and narrow environments of mass transportation like train cars or airplane cabins without giving off pungent odor of the sterilizers.

As TBI MOTION Chairperson Lee Ching Kun indicated that the productions this year are of a higher level that caters more to what people needed in real life. In line with Lee, Taichung City Economic Development Bureau leader Lu Yo Chih further pointed out the current problem of the limited land and space, and encouraged the students to think systematically to solve the problems of society with their specialties.

“The productions this year demonstrate their innovative ideas and inter-disciplinary application that correspond to the integrating concept of I4,” commented one of the judges, Professor Liu De Shin from National Chung Cheng University. “It was difficult for me to decide which one is the best, since each team and each work is good enough to be the best.”