Eco-friendly Oyster Shell Brick Earns Certification

Article courtesy Taipei Times (Staff writer, with CNA)

An eco-friendly brick made from oyster shells and furnace slag that was the brainchild of academics at National Taipei University of Technology has earned Cradle to Cradle (C2C) certification for being safe, circular and responsibly made.

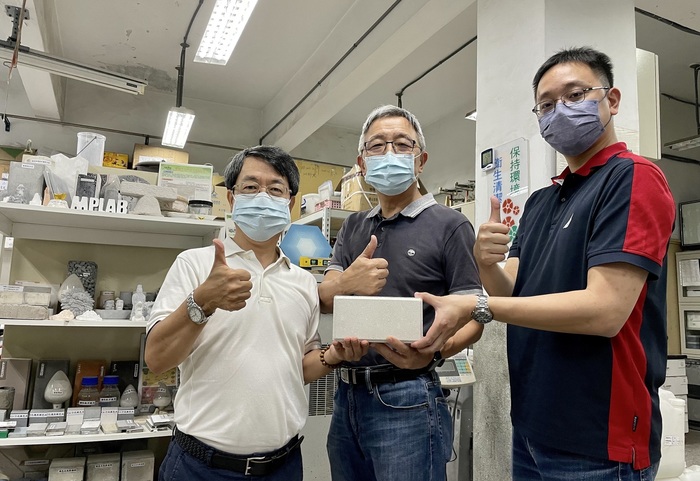

The brick was an innovation of Shao Wen-cheng (邵文政), a lecturer in the university’s Innovative Green Building Materials Research and Promotion Center, and Cheng Ta-wui (鄭大偉) and Lee Wei-hao (李韋皞), who teach in the Institute of Mineral Resources Engineering, the university said in a news release on Friday.

They mix powdered oyster shells, slag from a steel plant’s blast furnace and lye, and put the mixture in a mold to produce the bricks, the research team said.

It is one of the first times anywhere in the world that a patented university product has gained C2C certification, the university said.

During a visit to Makung Junior High School in Penghu County in 2019 to raise awareness of circular economy concepts, Shao discovered piles of oyster shells abandoned by local oyster farmers outside the campus, he told reporters in a telephone interview.

Chuang hao-chih (莊浩志), the junior-high school’s director of general affairs who was guiding Shao during his visit, said that the shells were trash, but the professor saw value in them, Shao said.

“To me, those shells were not garbage. They were actually building materials,” he said.

To demonstrate how the circular economy works, Shao asked Chuang to send him the shells, from which the team made bricks and sent them back to Chuang to use at the school.

Shao had other bricks from the project evaluated by organizations that specialize in sustainability, including the Green Building Materials Mark and the Taiwan branch of the Environmental Protection Encouragement Agency.

It was their positive feedback and the support of Kuo Yang Construction that encouraged the team to apply for top-tier C2C certification, he said.

C2C assesses the safety, circularity and responsible use of materials across five categories: Material health, product circularity, clean air and climate protection, water and soil stewardship, and social fairness, the Cradle to Cradle Products Innovation Institute’s Web site says.

The brick was awarded a bronze label, the fourth-highest on a five-tier scale of overall circularity.

Compared with conventional bricks, which require a lot of electricity in a process that is carbon emissions heavy, the shell brick stood out because it takes much less water, power and carbon to produce, the team said.

A downside is that the shell brick costs more than a standard brick to produce, but the team said the cost gap would narrow if it is mass produced.

Taiwan produces more than 100,000 tonnes of waste oyster shells a year that could be used to make the eco- friendly bricks, the university said.